SanHok Product

TV Assembly Aging Testing Line

TV assembly line is composed of production line, aging line, and moving table. Its size can be customized according to the area of the work shop.

It is suitable for TV production of all sizes, from 15 inches to 65 inches.

The most used TV production lines are 43 inches, 55 inches, and 65 inches led tv assembly line.

Contact us for a price

Speak To A Conveyer Specialist

Specifications

SanHok TV Assembly Aging Testing Line

| 1. Assembly Line | Line: automatic, PLC control system, 2 rows aging line, 8 sets pallet stopper. Four sections stops by QX-4 pallet stopper. Pallet-In stops by QX-2 pallet stopper. |

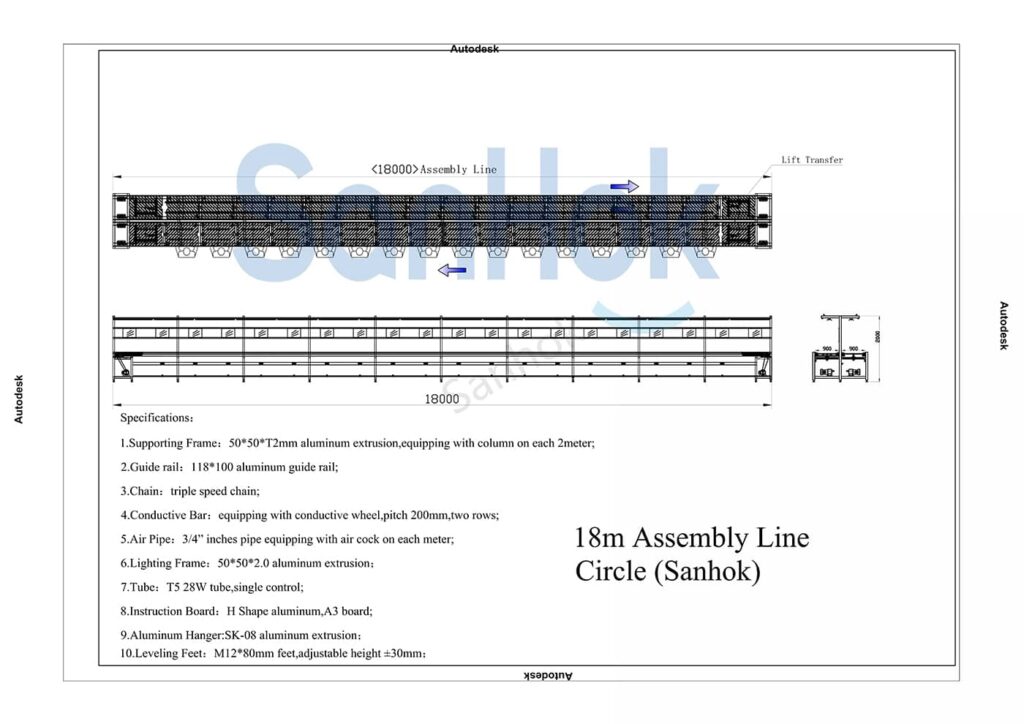

2. Support Frame | 50 *50 aluminum, guiderail aluminum only, three-speed chain, galvanized air pipe. Line equipping with rapid joint with Y shape |

| 3. Motor of Assembly Line | 2 HP, 1:100 gear reducer motor, total 8 sets. B1 and B2 adopts 0.5 HP, 1:80 motor, total 2 sets. | 4. Moving Table | Moving Table adopts MGPM63-50. Equipping with motor 90 w, 1:30 gear box, Chuanming brand. |

| 5. Conductive Frame | Conductive frame made of aluminum. Shrouding plate in 1.5mm thick, coating treatment. | 6. Conductive Guide Rail | Conductive guiderail made of aluminum alloy coating with plastic. Note: 1. Each pallet equipped with 2 sockets with 2 seats in 3 holes. 2. Pallet stopper all automatic. |

| 7. Electric Box | Electric Box: Adopts Japan brand Mitsubishi, PLC control. | 8. Static Wire | Static Wire: 4 m², equipped in the foot of all lines. Conveying belt device adopts 5mm thick, anti-skidding belt. Conveying axle adopts A3 plate, conveying wheel adopts rubber with wheels. |

| 9. Pallet Stopper | Pallet Stopper: QX-2 stopper on steel plate in 3 mm thick. Foot valve control, total 42 sets. |

10. Foot Valve | Foot Valve: Each workstation equipped with a foot valve. |

| 11. Motor of Moving Table | Motor of Moving Table: 90 w motor, 1:30 gear box. Total 8 sets of moving device. | 12. Stroke Switch | Stroke Switch: OMRON brand. |

| 13. Shrouding Plate | Shrouding Plate: 1.5 Y steel plate. Static coating. | ||

1. Assembly Line: automatic, PLC control system, 2 rows aging line, 8 sets pallet stopper. Four sections stops by QX-4 pallet stopper. Pallet-In stops by QX-2 pallet stopper.

2. Support Frame: 50 *50 aluminum, guiderail aluminum only, three-speed chain, galvanized air pipe. Line equipping with rapid joint with Y shape.

3. Motor of Assembly Line: 2 HP, 1:100 gear reducer motor, total 8 sets. B1 and B2 adopts 0.5 HP, 1:80 motor, total 2 sets.

4. Moving Table: Moving Table adopts MGPM63-50. Equipping with motor 90 w, 1:30 gear box, Chuanming brand.

5. Conductive Frame: Conductive frame made of aluminum. Shrouding plate in 1.5mm thick, coating treatment.

6. Conductive Guide Rail: Conductive guiderail made of aluminum alloy coating with plastic.

Note:

- Each pallet equipped with 2 sockets with 2 seats in 3 holes.

- Pallet stopper all automatic.

7. Electric Box: Electric Box: Adopts Japan brand Mitsubishi, PLC control.

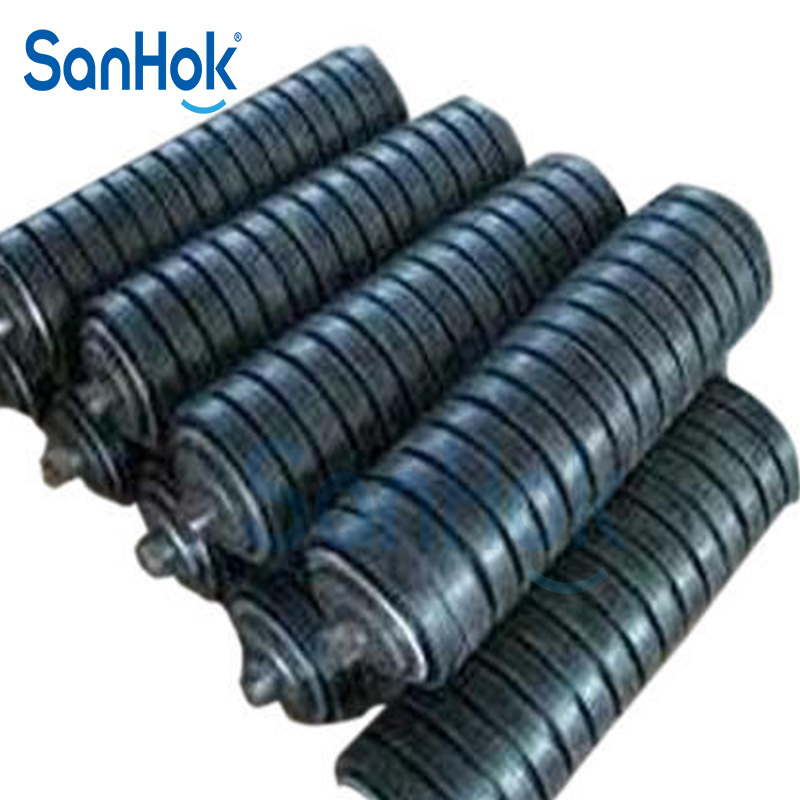

8. Static Wire: Static Wire: 4 m², equipped in the foot of all lines. Conveying belt device adopts 5mm thick, anti-skidding belt. Conveying axle adopts A3 plate, conveying wheel adopts rubber with wheels.

9. Pallet Stopper: Pallet Stopper: QX-2 stopper on steel plate in 3 mm thick. Foot valve control, total 42 sets.

10. Foot Valve: Foot Valve: Each workstation equipped with a foot valve.

11. Motor of Moving Table: Motor of Moving Table: 90 w motor, 1:30 gear box. Total 8 sets of moving device.

12. Stroke Switch: Stroke Switch: OMRON brand.

13. Shrouding Plate: Shrouding Plate: 1.5 Y steel plate. Static coating.

Features

Maximize Efficiency and Durability

Engineered with precision and built with high-quality materials, these rollers ensure smooth, reliable operation under even the heaviest loads. With a range of customizable sizes and surface treatments, our rollers are perfect for a variety of industries including manufacturing, logistics, and material handling.

Successful Cases

SanHok TV Line Successful Cases

TV Assembly Line Conveyor Part 1

TV Assembly Line Conveyor Part 2

Electric Box

Control Screen

Elevator Design

TV Aging Design

TV Aging Design Part 2

Package Line

Услуги

Customization Steps

1. What sizes of tv will be assembled?

2. The production capacity?

3. Need aging or not?

4. Need the workshop layout.

Contact us for a price

Speak To A Conveyer Specialist

Аксессуары 样式1

Enhance Your Assembly Line With Our Premium Accessories

<script>

document.addEventListener('DOMContentLoaded', () => {

const FBautoplayTime = 5; // Set autoplay time in secounds

// Seleccionar todos los conjuntos de tabs

const tabsSets = document.querySelectorAll('[fb-tabs]');

tabsSets.forEach(tabsSet => {

const tabs = tabsSet.querySelectorAll('[fb-tabs-btn]');

const panels = tabsSet.querySelectorAll('[fb-tabs-panel]');

const tabsMenu = tabsSet.querySelector('[fb-tabs-menu]');

const tabsTitle = tabsSet.querySelector('[fb-tabs-title]');

const isVertical = tabsSet.hasAttribute('fb-vertical');

// Añadir la variable CSS --fb-progress-time al estilo de [fb-tabs]

tabsSet.style.setProperty('--fb-progress-time', `${FBautoplayTime}s`);

// Asignar aria-label del menú de tabs con el texto del título

if (tabsMenu && tabsTitle) {

tabsMenu.setAttribute('aria-label', tabsTitle.textContent.trim());

}

// Asignar aria-controls a los tabs y aria-label a los paneles

if (tabs.length === panels.length) {

tabs.forEach((tab, index) => {

const panelId = panels[index].id;

const tabText = tab.textContent.trim();

if (panelId && tabText) {

tab.setAttribute('aria-controls', panelId);

panels[index].setAttribute('aria-label', tabText);

}

tab.setAttribute('aria-selected', tab.classList.contains('brx-open'));

tab.setAttribute('tabindex', tab.classList.contains('brx-open') ? '0' : '-1');

});

}

// Configurar el MutationObserver

const observer = new MutationObserver((mutations) => {

mutations.forEach((mutation) => {

if (mutation.type === 'attributes' && mutation.attributeName === 'class') {

const targetTab = mutation.target;

targetTab.setAttribute('aria-selected', targetTab.classList.contains('brx-open'));

targetTab.setAttribute('tabindex', targetTab.classList.contains('brx-open') ? '0' : '-1');

}

});

});

// Observar cada tab para cambios en la clase

tabs.forEach((tab) => {

observer.observe(tab, { attributes: true });

});

let currentTabIndex = 0;

let autoplayInterval = null;

let hoverTimeout = null;

let isHovered = false;

let manualSelection = false;

const startAutoplay = () => {

autoplayInterval = setInterval(() => {

if (!manualSelection && !isHovered) {

const nextIndex = (currentTabIndex + 1) % tabs.length;

activateTab(nextIndex);

}

}, FBautoplayTime*1000); // Usar la constante para el tiempo del autoplay

};

const resetAutoplay = (index) => {

clearInterval(autoplayInterval);

activateTab(index);

manualSelection = true;

tabs.forEach((tab, idx) => {

tab.setAttribute('aria-selected', idx === currentTabIndex);

tab.setAttribute('tabindex', idx === currentTabIndex ? '0' : '-1');

panels[idx].classList.toggle('brx-open', idx === currentTabIndex);

});

setTimeout(() => {

manualSelection = false;

}, 100);

};

const activateTab = (index) => {

tabs[currentTabIndex].classList.remove('brx-open');

panels[currentTabIndex].classList.remove('brx-open');

currentTabIndex = index;

tabs[currentTabIndex].classList.add('brx-open');

panels[currentTabIndex].classList.add('brx-open');

tabs.forEach((tab, idx) => {

tab.setAttribute('aria-selected', idx === currentTabIndex);

tab.setAttribute('tabindex', idx === currentTabIndex ? '0' : '-1');

});

};

startAutoplay();

const handleHoverStart = () => {

isHovered = true;

tabsSet.classList.add('fb-tab-progress');

clearInterval(autoplayInterval);

};

const handleHoverEnd = () => {

isHovered = false;

tabsSet.classList.remove('fb-tab-progress');

if (!manualSelection) {

startAutoplay();

}

};

// Añadir manejadores de clic y hover para tabs

tabs.forEach((tab, index) => {

tab.addEventListener('click', () => {

resetAutoplay(index);

});

tab.addEventListener('focus', () => {

handleHoverStart();

});

tab.addEventListener('mouseenter', () => {

handleHoverStart();

});

tab.addEventListener('mouseleave', () => {

handleHoverEnd();

});

tab.addEventListener('keydown', (event) => {

if (event.key === 'Enter' || event.key === ' ') {

event.preventDefault();

resetAutoplay(index);

}

});

});

// Añadir manejadores de hover para paneles

panels.forEach((panel) => {

panel.addEventListener('mouseenter', () => {

handleHoverStart();

});

panel.addEventListener('mouseleave', () => {

handleHoverEnd();

});

});

// Manejo de eventos de teclado para navegación entre tabs

tabsSet.addEventListener('keydown', (event) => {

const currentTab = tabs[currentTabIndex];

if (event.key === 'ArrowRight' || (isVertical && event.key === 'ArrowDown')) {

event.preventDefault();

const nextIndex = (currentTabIndex + 1) % tabs.length;

resetAutoplay(nextIndex);

tabs[nextIndex].focus();

} else if (event.key === 'ArrowLeft' || (isVertical && event.key === 'ArrowUp')) {

event.preventDefault();

const nextIndex = currentTabIndex === 0 ? tabs.length - 1 : currentTabIndex - 1;

resetAutoplay(nextIndex);

tabs[nextIndex].focus();

} else if (event.key === 'Home') {

event.preventDefault();

resetAutoplay(0);

tabs[0].focus();

} else if (event.key === 'End') {

event.preventDefault();

resetAutoplay(tabs.length - 1);

tabs[tabs.length - 1].focus();

}

});

});

});

</script>

Линия сборки кондиционеров

Here goes your text ... Select any part of your text to access the formatting toolbar.

Product A

Product B

Product C

Product D

Product E

Product F

Battery Pack Production Line

Here goes your text ... Select any part of your text to access the formatting toolbar.

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Аксессуары

Enhance Your Assembly Line With Our Premium Accessories

Product A

Product B

Product C

Product D

Product E

Product F

Product F

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Поддерживать

Comprehensive Services And Support

Besides life long technical support, we also offer you service as below:

Shipment Of Machine

Installation

Training

Warranty

FAQ Guide

SanHok TV Assembly Aging Testing Line

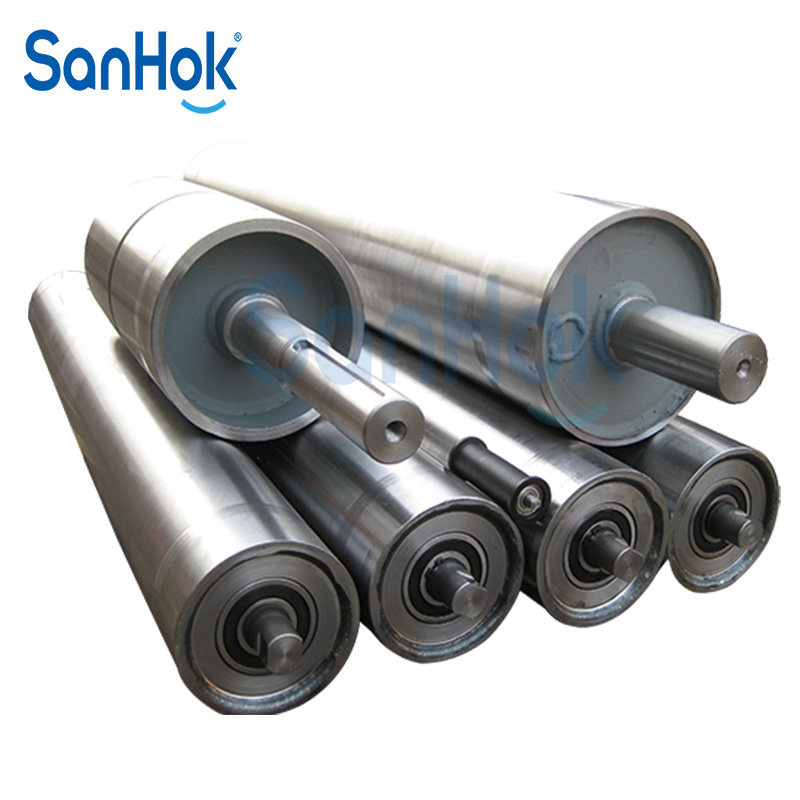

Q1: What is the material of the roller?

A: The roller can be made of stainless steel or carbon steel. The sprocket is generally made of carbon steel, or it can be customized according to the customer.

Q2: I have a drawing, can you customize it for me?

A: We support customized services, please mark the following information on the drawing: the length, diameter, material, wall thickness, and sprocket of the roller.

Q3: What is your delivery time?

A: Generally, 50,00 pcs–5-7 fast day delivery. If the quantity is large ,We need negotiation.