HUSQVARNA

The challenge

The challenge Husqvarna Group aimed to modernize its 45,000-square -meter production warehouse in Poland to increase capacities and gain automation efficiencies. With around 100 product variants and an annual volume of 160,000 pieces, efficient handling was imperative to face the challenge.

The solution

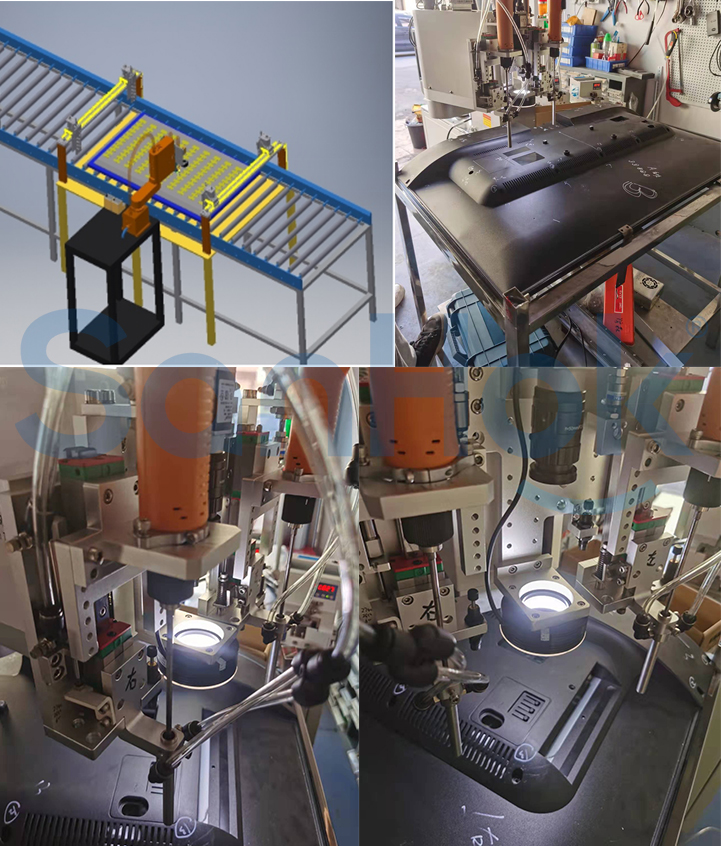

Interroll collaborated with LCLS, a leading system integrator, to modernize Husqvarna’s production warehouse. The modular, scalable solutions were tailored to Husqvarna’s needs and based on the entire portfolio of the Interroll Modular Conveyor Platform (MCP), including:

- Interroll conveyors to ensure seamless flow

- High-end sensors and low-voltage (24- and 48-volt) systems for better sustainability and ease of maintenance

- Zero-pressure-accumulation technology for the most efficient throughput possible

- Diverters for safe sortation processes.