SanHok Product

LED Lamp Assembly Line

The LED lamp assembly line consists of a production line, aging line, and packaging line. Its size can be customized to fit the workshop area, making it adaptable to various production environments. This assembly line is suitable for producing LED lamps of all sizes. For small-sized LED lamps, the assembly line uses a belt conveyor, while for larger-sized LED lamps, a speed chain conveyor is employed.

Contact us for a price

Speak To A Conveyer Specialist

Specifications

SanHok LED Lamp Assembly Line

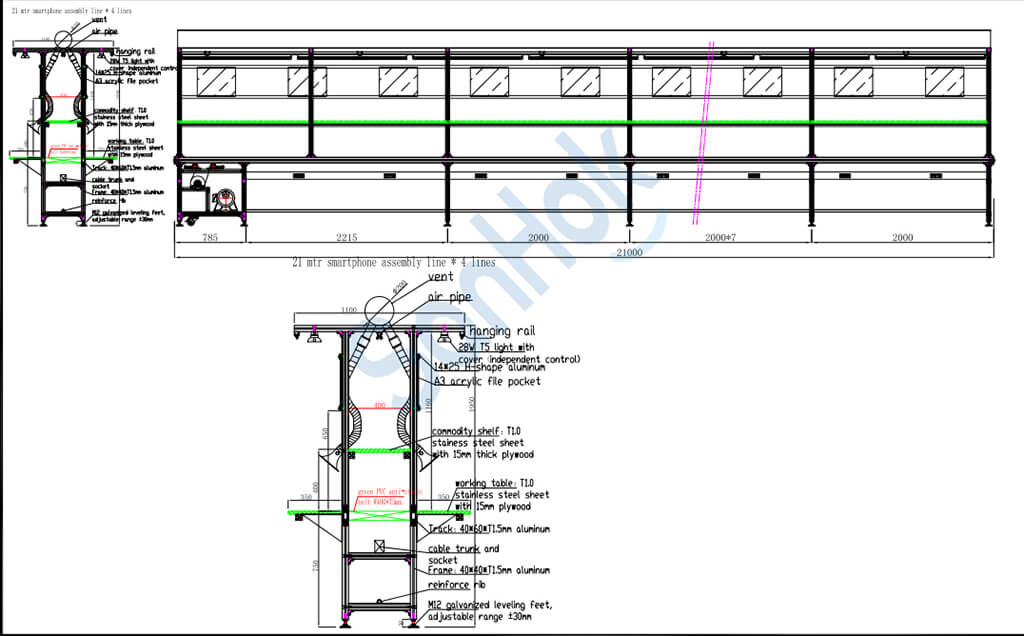

Motor – 2HP, 1:60 Cheeming brand motor, equipped with frequency speed controller.

Frame for Motor – 4040T2.0mm aluminum extrusion, A3 board shrouding in 1.0mm thickness, equipped with sprocket and chain.

Drawer – Equipped drawer in the line, thickness 1.2 mm, powder coating.

Guide Rail – 4060T1.5mm aluminum extrusion.

Support Frame – 4040T1.5mm aluminum extrusion, equipped with a column every 2000 mm, working height 750 mm.

Lighting – 28W, T5 tube.

Instruction Board – Support adopts 28*30 aluminum bars in H shape, green acrylic plate equipped with transparent A3 acrylic plate every meter.

Tool Hanging Rail – Support made of 28*30 aluminum, equipped with a set of wheels every meter.

Working Bench – 300 mm in width, 15 mm in thickness, pasted with PVC belt in 2 mm thickness, T-shape belt cover. Support frame made of 4040T1.2mm aluminum extrusion.

Plating Bench – T15 mm wooden board pasted with fireproof material, T-shape cover.

Wire Slot 60*80 – Galvanized board in 1.0 mm thickness, equipped with a socket every meter, using 4M² wire.

Conveying Belt – PVC belt in 2 mm thickness, 400 mm in width, jointless.

Supporting Board and Supporting Roller for Belt – Galvanized board in 1.0 mm thickness for support. Upper support roller: galvanized unpowered roller, 50 mm diameter. Down support roller: galvanized unpowered roller, 38 mm diameter. Rollers installed every 2000 mm.

Controlling Electrical Equipment – Equipped with 1 electric box, Chint brand switch inside.

Air Pipe – 3/4” galvanized pipe with air cock every meter for the entire line.

Leveling Feet – M12*80 galvanized feet, adjustable height 30 mm.

Working Bench – 300 mm in width, 15 mm in thickness, pasted with PVC belt in 2 mm thickness, T-shape belt cover. Support frame made of 4040T1.2mm aluminum extrusion.

Plating Bench – T15 mm wooden board pasted with fireproof material, T-shape cover.

Wire Slot 60*80 – Galvanized board in 1.0 mm thickness, equipped with a socket every meter, using 4M² wire.

Conveying Belt – PVC belt in 2 mm thickness, 400 mm in width, jointless.

Supporting Board and Supporting Roller for Belt – Galvanized board in 1.0 mm thickness for support. Upper support roller: galvanized unpowered roller, 50 mm diameter. Down support roller: galvanized unpowered roller, 38 mm diameter. Rollers installed every 2000 mm.

Controlling Electrical Equipment – Equipped with 1 electric box, Chint brand switch inside.

Air Pipe – 3/4” galvanized pipe with air cock every meter for the entire line.

Leveling Feet – M12*80 galvanized feet, adjustable height 30 mm.

Features

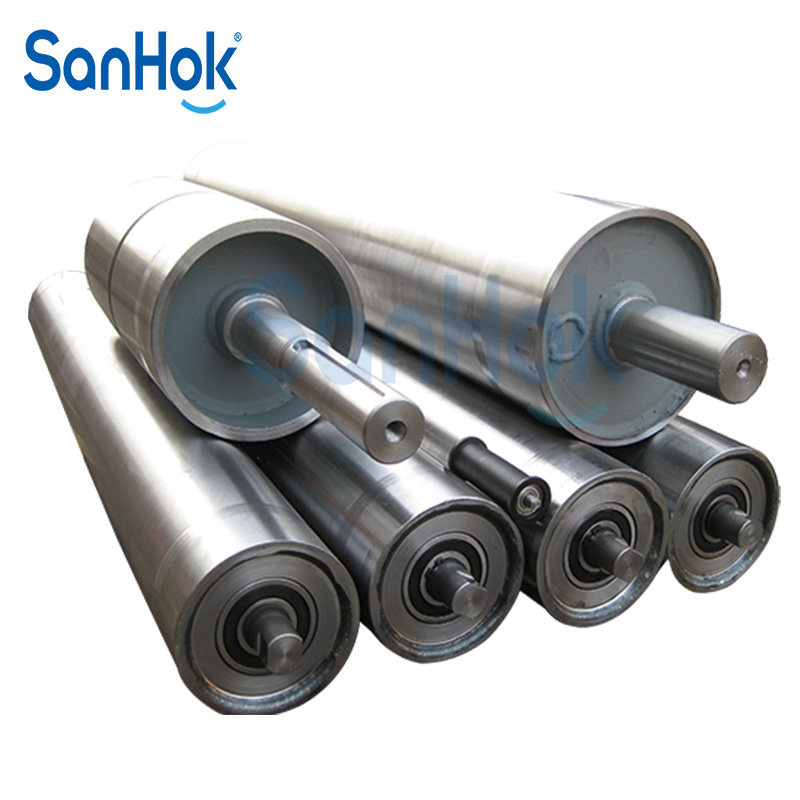

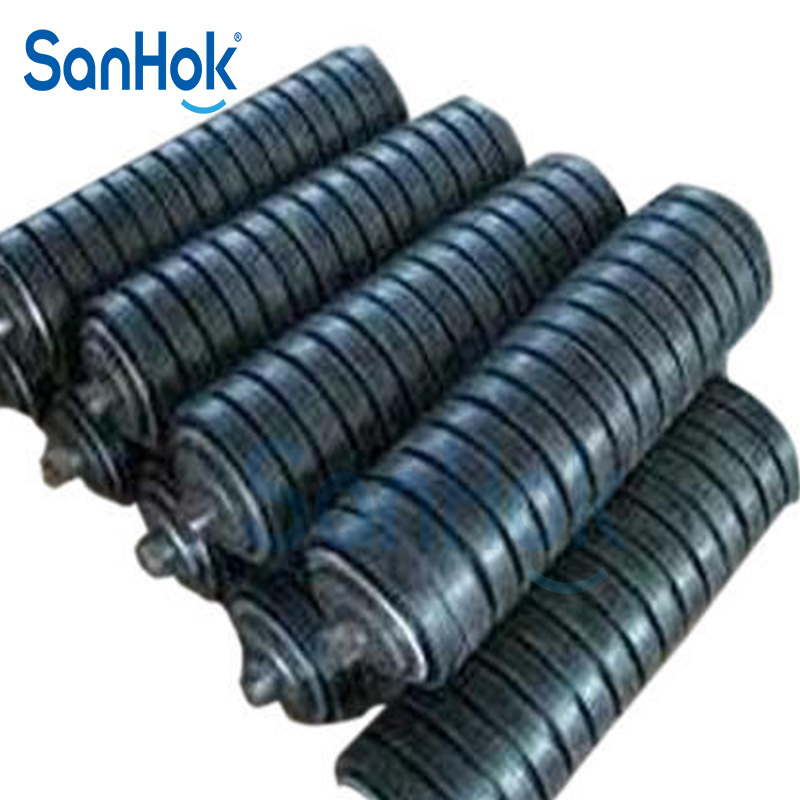

Maximize Efficiency and Durability

Engineered with precision and built with high-quality materials, these rollers ensure smooth, reliable operation under even the heaviest loads. With a range of customizable sizes and surface treatments, our rollers are perfect for a variety of industries including manufacturing, logistics, and material handling.

Successful Cases

SanHok LED Lamp Assembly Line Successful Cases

Led Lamp Assembly Line Part 1

Led Lamp Assembly Line Part 2

Led Lamp Assembly Line Part 3

Led Lamp Assembly Line Part 4

Led Lamp Assembly Line Part 5

Led Lamp Assembly Line Part 6

Services

Customization Steps

1. What kind of led lamp to be assembled

2. What the dimension of lamp

3. What the production capacity

4. Need the workshop layout

Contact us for a price

Speak To A Conveyer Specialist

Accessories 样式1

Enhance Your Assembly Line With Our Premium Accessories

<script>

document.addEventListener('DOMContentLoaded', () => {

const FBautoplayTime = 5; // Set autoplay time in secounds

// Seleccionar todos los conjuntos de tabs

const tabsSets = document.querySelectorAll('[fb-tabs]');

tabsSets.forEach(tabsSet => {

const tabs = tabsSet.querySelectorAll('[fb-tabs-btn]');

const panels = tabsSet.querySelectorAll('[fb-tabs-panel]');

const tabsMenu = tabsSet.querySelector('[fb-tabs-menu]');

const tabsTitle = tabsSet.querySelector('[fb-tabs-title]');

const isVertical = tabsSet.hasAttribute('fb-vertical');

// Añadir la variable CSS --fb-progress-time al estilo de [fb-tabs]

tabsSet.style.setProperty('--fb-progress-time', `${FBautoplayTime}s`);

// Asignar aria-label del menú de tabs con el texto del título

if (tabsMenu && tabsTitle) {

tabsMenu.setAttribute('aria-label', tabsTitle.textContent.trim());

}

// Asignar aria-controls a los tabs y aria-label a los paneles

if (tabs.length === panels.length) {

tabs.forEach((tab, index) => {

const panelId = panels[index].id;

const tabText = tab.textContent.trim();

if (panelId && tabText) {

tab.setAttribute('aria-controls', panelId);

panels[index].setAttribute('aria-label', tabText);

}

tab.setAttribute('aria-selected', tab.classList.contains('brx-open'));

tab.setAttribute('tabindex', tab.classList.contains('brx-open') ? '0' : '-1');

});

}

// Configurar el MutationObserver

const observer = new MutationObserver((mutations) => {

mutations.forEach((mutation) => {

if (mutation.type === 'attributes' && mutation.attributeName === 'class') {

const targetTab = mutation.target;

targetTab.setAttribute('aria-selected', targetTab.classList.contains('brx-open'));

targetTab.setAttribute('tabindex', targetTab.classList.contains('brx-open') ? '0' : '-1');

}

});

});

// Observar cada tab para cambios en la clase

tabs.forEach((tab) => {

observer.observe(tab, { attributes: true });

});

let currentTabIndex = 0;

let autoplayInterval = null;

let hoverTimeout = null;

let isHovered = false;

let manualSelection = false;

const startAutoplay = () => {

autoplayInterval = setInterval(() => {

if (!manualSelection && !isHovered) {

const nextIndex = (currentTabIndex + 1) % tabs.length;

activateTab(nextIndex);

}

}, FBautoplayTime*1000); // Usar la constante para el tiempo del autoplay

};

const resetAutoplay = (index) => {

clearInterval(autoplayInterval);

activateTab(index);

manualSelection = true;

tabs.forEach((tab, idx) => {

tab.setAttribute('aria-selected', idx === currentTabIndex);

tab.setAttribute('tabindex', idx === currentTabIndex ? '0' : '-1');

panels[idx].classList.toggle('brx-open', idx === currentTabIndex);

});

setTimeout(() => {

manualSelection = false;

}, 100);

};

const activateTab = (index) => {

tabs[currentTabIndex].classList.remove('brx-open');

panels[currentTabIndex].classList.remove('brx-open');

currentTabIndex = index;

tabs[currentTabIndex].classList.add('brx-open');

panels[currentTabIndex].classList.add('brx-open');

tabs.forEach((tab, idx) => {

tab.setAttribute('aria-selected', idx === currentTabIndex);

tab.setAttribute('tabindex', idx === currentTabIndex ? '0' : '-1');

});

};

startAutoplay();

const handleHoverStart = () => {

isHovered = true;

tabsSet.classList.add('fb-tab-progress');

clearInterval(autoplayInterval);

};

const handleHoverEnd = () => {

isHovered = false;

tabsSet.classList.remove('fb-tab-progress');

if (!manualSelection) {

startAutoplay();

}

};

// Añadir manejadores de clic y hover para tabs

tabs.forEach((tab, index) => {

tab.addEventListener('click', () => {

resetAutoplay(index);

});

tab.addEventListener('focus', () => {

handleHoverStart();

});

tab.addEventListener('mouseenter', () => {

handleHoverStart();

});

tab.addEventListener('mouseleave', () => {

handleHoverEnd();

});

tab.addEventListener('keydown', (event) => {

if (event.key === 'Enter' || event.key === ' ') {

event.preventDefault();

resetAutoplay(index);

}

});

});

// Añadir manejadores de hover para paneles

panels.forEach((panel) => {

panel.addEventListener('mouseenter', () => {

handleHoverStart();

});

panel.addEventListener('mouseleave', () => {

handleHoverEnd();

});

});

// Manejo de eventos de teclado para navegación entre tabs

tabsSet.addEventListener('keydown', (event) => {

const currentTab = tabs[currentTabIndex];

if (event.key === 'ArrowRight' || (isVertical && event.key === 'ArrowDown')) {

event.preventDefault();

const nextIndex = (currentTabIndex + 1) % tabs.length;

resetAutoplay(nextIndex);

tabs[nextIndex].focus();

} else if (event.key === 'ArrowLeft' || (isVertical && event.key === 'ArrowUp')) {

event.preventDefault();

const nextIndex = currentTabIndex === 0 ? tabs.length - 1 : currentTabIndex - 1;

resetAutoplay(nextIndex);

tabs[nextIndex].focus();

} else if (event.key === 'Home') {

event.preventDefault();

resetAutoplay(0);

tabs[0].focus();

} else if (event.key === 'End') {

event.preventDefault();

resetAutoplay(tabs.length - 1);

tabs[tabs.length - 1].focus();

}

});

});

});

</script>

Air Conditioner Assembly Line

Here goes your text ... Select any part of your text to access the formatting toolbar.

Product A

Product B

Product C

Product D

Product E

Product F

Battery Pack Production Line

Here goes your text ... Select any part of your text to access the formatting toolbar.

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Accessories

Enhance Your Assembly Line With Our Premium Accessories

Product A

Product B

Product C

Product D

Product E

Product F

Product F

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Product A

Product B

Product C

Product D

Product E

Product F

Support

Comprehensive Services And Support

Besides life long technical support, we also offer you service as below:

Shipment Of Machine

Installation

Training

Warranty

FAQ Guide

SanHok LED Lamp Assembly Line

Q1: What is the size of the LED lamp assembly line?

A: The standard size of the assembly line is 2000900750 mm. However, it can be customized according to your production output and workshop requirements.

Q2: What sizes of LED lamps can the assembly line accommodate?

A: The assembly line is designed to handle LED lamps of all sizes, making it versatile for various production needs.

Q3: How long is the warranty period for this assembly line?

A: The warranty period for the assembly line is generally one year.

Q4: What materials are used in the construction of this machine?

A: The machine is constructed using high-quality aluminum alloy and carbon steel, ensuring durability and reliability.

Q5: How is maintenance performed on the assembly line?

A: We provide additional accessories with the assembly line. In case of any component failure, these accessories can be replaced immediately to minimize downtime.

Q6: How is installation handled for overseas customers?

A: We dispatch our professional installation team to oversee the installation process at your location, ensuring the assembly line is set up and operational efficiently.